The art of compounded strength

Hedrad EcoWasp technology has been evolved over a decade of research and demanding tests globally.

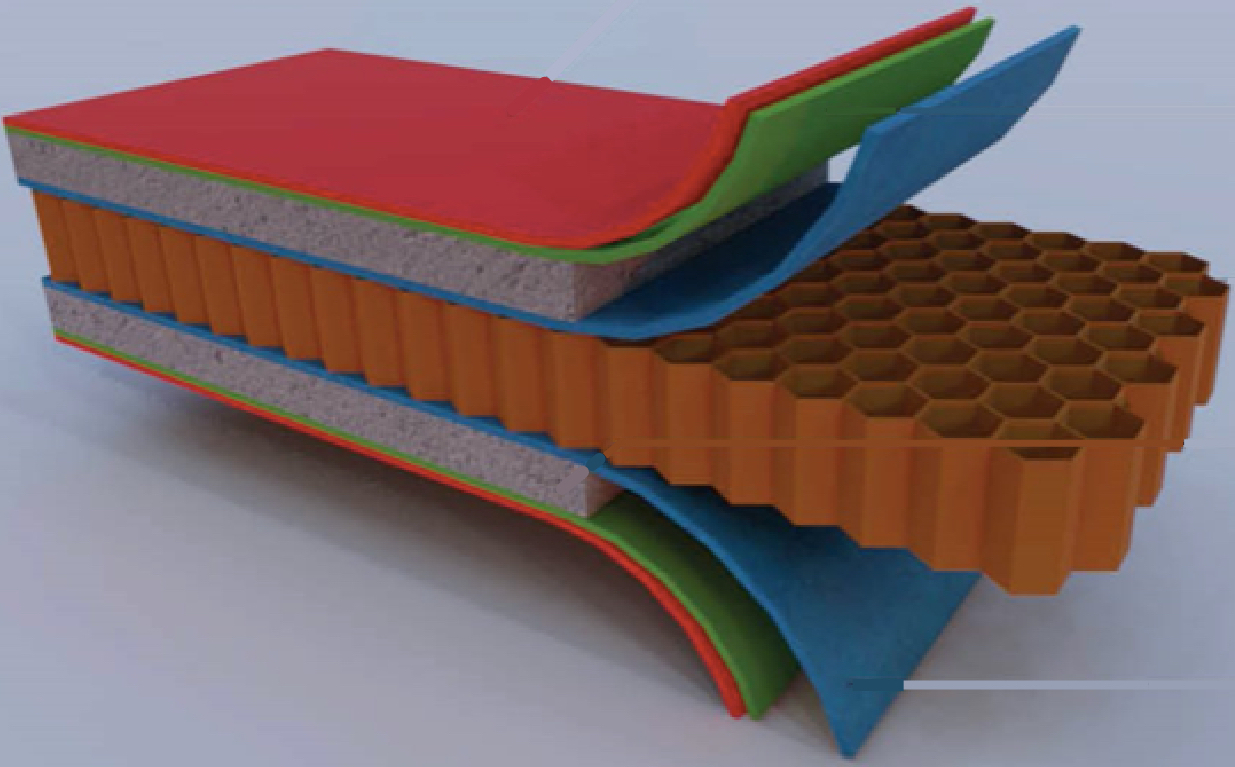

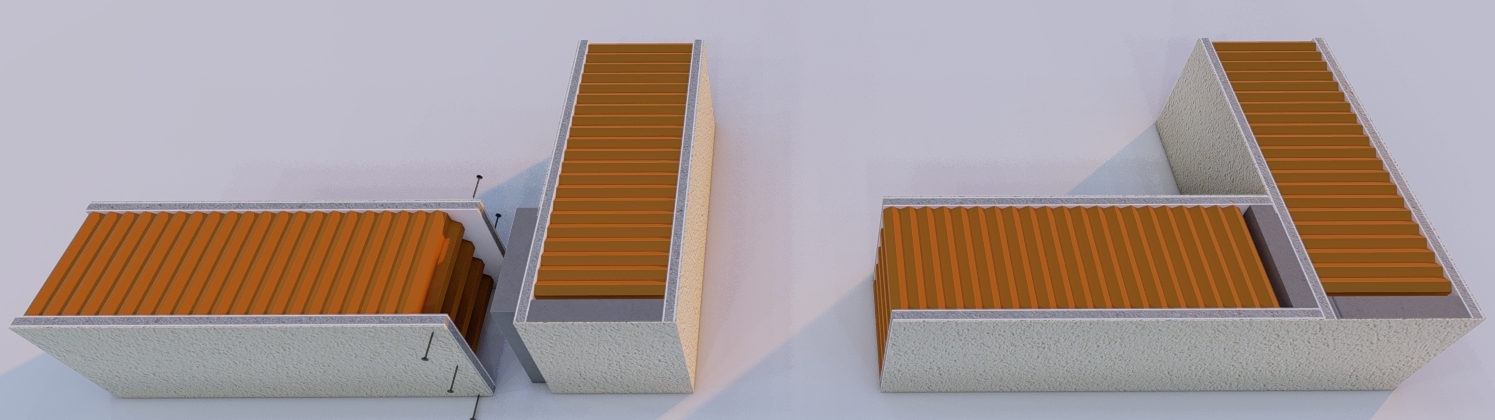

The key component with Hedrad EcoWasp technology is the modular Hedrad composite sandwich panels that can be used as walls, supports or panels to make anything from a box to a factory.

The resultant benefits are the best-in-class for any construction material.